slot die coating head|die coating process : Manila Solution metering is required in slot die systems because the delivery of solution has a significant impact on the uniformity of the coating and the actual thickness of the film. . Tingnan ang higit pa The safest and most inclusive global community of photography enthusiasts. The best place for inspiration, connection, and sharing!Sabong Worldwide – Your Gateway to Thrilling Casino Entertainment in the Philippines. Immerse in unmatched excitement and captivating games Live E-Sabong live actions. With unwavering excellence, a diverse game range, and an inviting interface, SabongWorldwide is your ultimate haven for deluxe Online Sabong and Casino leisure.

PH0 · slot die manufacturers

PH1 · slot die coating thickness

PH2 · slot die coating theory

PH3 · slot die coating process

PH4 · slot die coating book

PH5 · slot die coater

PH6 · fom slot die

PH7 · die coating process

PH8 · Iba pa

El Club Gastronómico es un juego de azar bastante popular en Neopia, conocido por su nombre en inglés: The Food Club.En esta guía te mostramos todo lo que tienes que saber sobre el jugo, los piratas y para hacer tus apuestas.

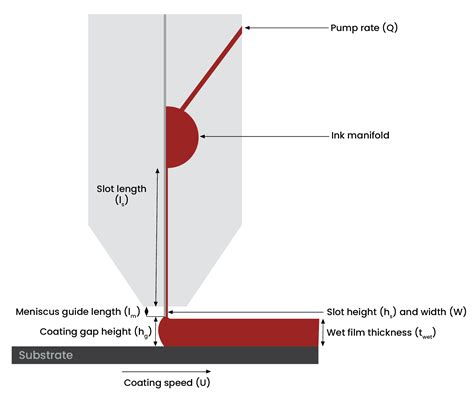

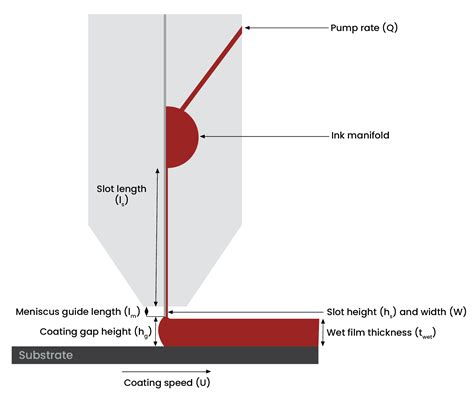

slot die coating head*******One of the most complex aspects of a slot die coating system is the design of the slot die head. The head controls the distribution of solution across the width of coating, the actual coating width of the film, and also helps determine the stability of the coating process. The figure below . Tingnan ang higit paIn this guide, we introduce the concept behind slot die coating as a deposition technique and explain the theory that underpins . Tingnan ang higit paSlot die coating is part of a family of techniques which are classed as pre-metered coating techniques. For pre-metered deposition, the final film thickness is . Tingnan ang higit pa

Solution metering is required in slot die systems because the delivery of solution has a significant impact on the uniformity of the coating and the actual thickness of the film. . Tingnan ang higit paThe design and build of a slot die coater is based around providing a uniform delivery of solution to a given surface. This single simplified requirement can be difficult to manage . Tingnan ang higit pa

Slot-die coating is a coating technique for the application of solution, slurry, or extruded thin films onto typically flat substrates such as glass, metal, paper, fabric or plastic foils. The process was first developed for the industrial production of photographic papers in the 1950's. It has since become relevant in numerous commercial processes and nanomaterials related research fields.Slot-die coating is a highly scalable technique for rapidly depositing thin and uniform films with minimal material waste and low operational cost. Slot-die coating technology is .slot die coating head die coating process Design Issues for Slot-Die Coating Heads - Case S tudy Ferenc Sarka 1 (0000-0003-3136-4248), Zsolt Tóbis 1 (0000-0002-4711-2224) 1 University of Miskolc, .Slot-die Head width (cm) Max. coating width (cm) Std. shim sizes (cm) Small 6.5 2.5 0.5 1 1.3 2 2.5 Medium 9 5 5 Large 14 10 10 XL 20 15 15 . 3 FOM TECHNOLOGIES A/S .

Slot-die systems achieve their coatings by delivering the desired coating fluid (often referred to as “ink”) onto the substrate through a highly precise delivery component known as the “slot-die head.” The slot-die head .die coating processSlot-die systems achieve their coatings by delivering the desired coating fluid (often referred to as “ink”) onto the substrate through a highly precise delivery component known as the “slot-die head.” The slot-die head . For a typical slot-die coating process a coating head is positioned close to and across a substrate or web, ink is then pumped into the head, using a syringe pump, .

Key Features. Compact Size. Coating/Printing Width From 10-280 mm. Modular Drying/Curing System. Glovebox Compatible. Software Control Option. Tension Control. CE Certified - CSA/UL Compliant. .

Abstract. In this article, the authors briefly present the development, features, operating principles, and typical applications of slot-die technology. Slot-die technology .The dead volume for the laboratory slot-die coating heads ranges from hundreds of microliters to a few milliliters. Our larger pilot and industrial scale slot-die heads have a large dead volume starting from around 2 .

Slot-die coating. Slot-die coating is a new precise method for depositing a thin liquid film to the surface of a substrate. It was developed to provide a more efficient, cost-optimized, and scalable coating method. Slot-die .

The slot-die coating process was invented by Beguin from Eastman Kodak Company [57], in order to get over the drawbacks or restrictions of existing coating techniques, . perovskite ink is delivered to a moving substrate through a narrow trough in the slot die head. Two menisci are formed upstream and downstream of the coating .

Slot-die Head width (cm) Max. coating width (cm) Std. shim sizes (cm) Small 6.5 2.5 0.5 1 1.3 2 2.5 Medium 9 5 5 Large 14 10 10 XL 20 15 15 . 3 FOM TECHNOLOGIES A/S Enabling Functional Materials R&D [email protected] Artillerivej .

The coating method as shown in the image below, works by dissolving the material to be dispensed into a solution with a suitable viscosity (1). This solution is then pumped into the slot die head (2), where it is dispensed across the width of the substrate. The substrate then moves (3) beneath the slot die coat head and a smooth film is . Design Issues for Slot-Die Coating Heads - Case Study. Ferenc Sarka 1 and Zsolt Tóbis 1. . Slot-die technology is a coating method in which a consistent thickness, coating layer, can be applied to a receiving surface in an almost completely closed system. The technology was first used in the production of films but is now used for the .

Our slot die coater is fully operable using the digital controls. You can easily program multi-step processes to independently control the temperature, substrate speed, alignment, solution flow rate, channel thickness, head height, and more. Save 20 of these programmes, each with up to 50 steps, for easy and repeatable experiments.The infinityPV slot-die heads are engineered with precision and composition in mind, allowing for consistent and uniform coating thickness, resulting in high-quality end products. Whether you are working with batteries, printed solar cells, OLEDs, sensors, or other thin-film technology, our slot-die heads are versatile and can accommodate a . But on large scale applications, slot die coating really starts to show its advantages. While comma head coating is the most common method for coating transdermals, slot die coating offers a whole host of additional benefits. I hope this post was helpful to you and your decision to include either comma head or slot die coating .

Coating Tech Slot Dies has developed this handy online technical calculator to easily complete complex calculations for flow rate, coating weight conversion, fluid die torque, surface energy, and equipment return on investment (ROI). . Coating Tech Slot Dies Corporate Headquarters 2322 Alpine Road, Suite 4 Eau Claire, WI 54703Slot Die Head Coating Width: 50 mm: Slot Die Shim Thickness: 100 μm: Luer Lock Adapter: Stainless Steel M5 to Luer Lock Adapter: Tubing and Connector Material: PTFE Tubing, high density PP Luer lock . The manifold of the slot die is designed for the rheological family of fluids you will be running through the coating head. In other words, don’t expect an adhesive slot die to run anode battery slurry. . For stripe coating using slot-die coating, a slot-die head with a shim and a meniscus guide is required. The shim mask is embedded into the head to define the feed slot width. Depending on the shim .Slot-die coating is a premetered process and state of the art in large-scale battery-cell production. After the mixing step, the electrode coating is applied to the current collector and dried in a slot-nozzle floatation dryer. After calendering, the electrodes are cut to size, stacked or rolled, and assembled into cells. Design Issues for Slot-Die Coating Heads - Case S tudy Ferenc Sarka 1 (0000-0003-3136-4248), Zsolt Tóbis 1 (0000-0002-4711-2224) 1 University of Miskolc, Institute of Machine and P roduct Design .

The slot-die heads are intended for operation at low pressure with low viscosity inks are comprised of only two parts which greatly simplify assembly, disassembly, and cleaning. They can be operated with a single shim or with a shim kit comprising shim and meniscus guide for coating stripes at low web speeds (0.1 - 5 m/min).Slot-die heads | Steel Series. Our slot-die heads are a piece of state-of-the-art coating equipment. Each coating head has been designed to fulfill the need for professional slot-die coating components. Produced from some of the hardest steel in the world, the material undergoes meticulous processes to provide stable and ultra-precise accuracy.용액코팅의 slot die산업계에서 수십 년의 경험 Slot Die코팅 산업계의 전문가와 일할 수 있습니다. Coating Tech Slot Dies사의 주역들은 해외 유명 업체에서의 산업 현장 경험을 토대로 고객 여러분께 필요한 코팅 공정 및 달성 목표를 명확하게 숙지하고 있습니다.

Batingan is a barangay in the municipality of Binangonan, province of Rizal, CALABARZON (Region IV-A), Philippines. The latest population is 16,280 (2020 Census figures). . Rizal: Municipality: Binangonan: Postal code: 1940: Population (2020) 16,280: Philippine major island(s) Luzon: Coordinates:Discover the world's largest mod repository on CurseForge, serving popular games and communities like Minecraft, WoW, The Sims 4, and more.

slot die coating head|die coating process